Understandably, choosing a good quality high performing Brake Rotor is as critical as choosing brake pads. Together they perform as one united component– combining to provide the stopping power needed in normal operating conditions as well as in high stopping emergency situations.

The great advantage of NiBK brake pads is that NiBK ROTOR FRIENDLY Technology and Low Dust formulation keeps your brake disc lasting longer and leaves your wheels cleaner. Installing NiBK on brand new or undamaged brake pads and rotors and using NiBK pads continuously you will see great improvement in your rotor lifespan. With the combination of NiBK pads and rotors, you will see the best performance result of both.

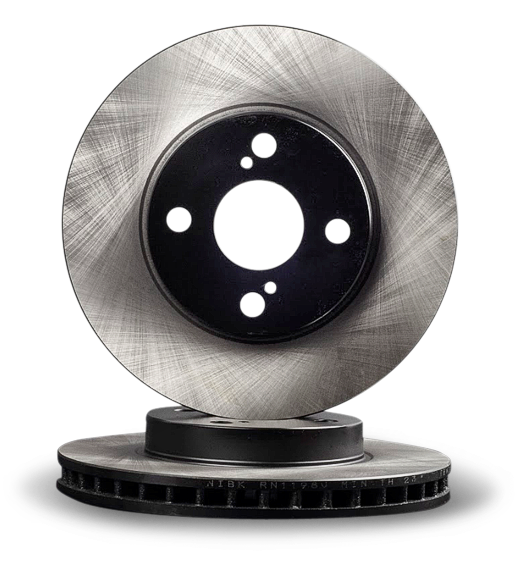

All NIBK brake rotors are manufactured to match the exact OE fit, OE construction, and precision finishing to ensure quick and easy installation, as well as trouble-free functionality for the life of the rotor. NIBK Brake Rotors are designed to provide the finest braking experience – from break in throughout the life of the rotor, reducing the chance of warping even under extreme braking temperatures.